- Home

- >

- Products

- >

- Gas Generator Sets

- >

- The Fuel Gas Generator Sets

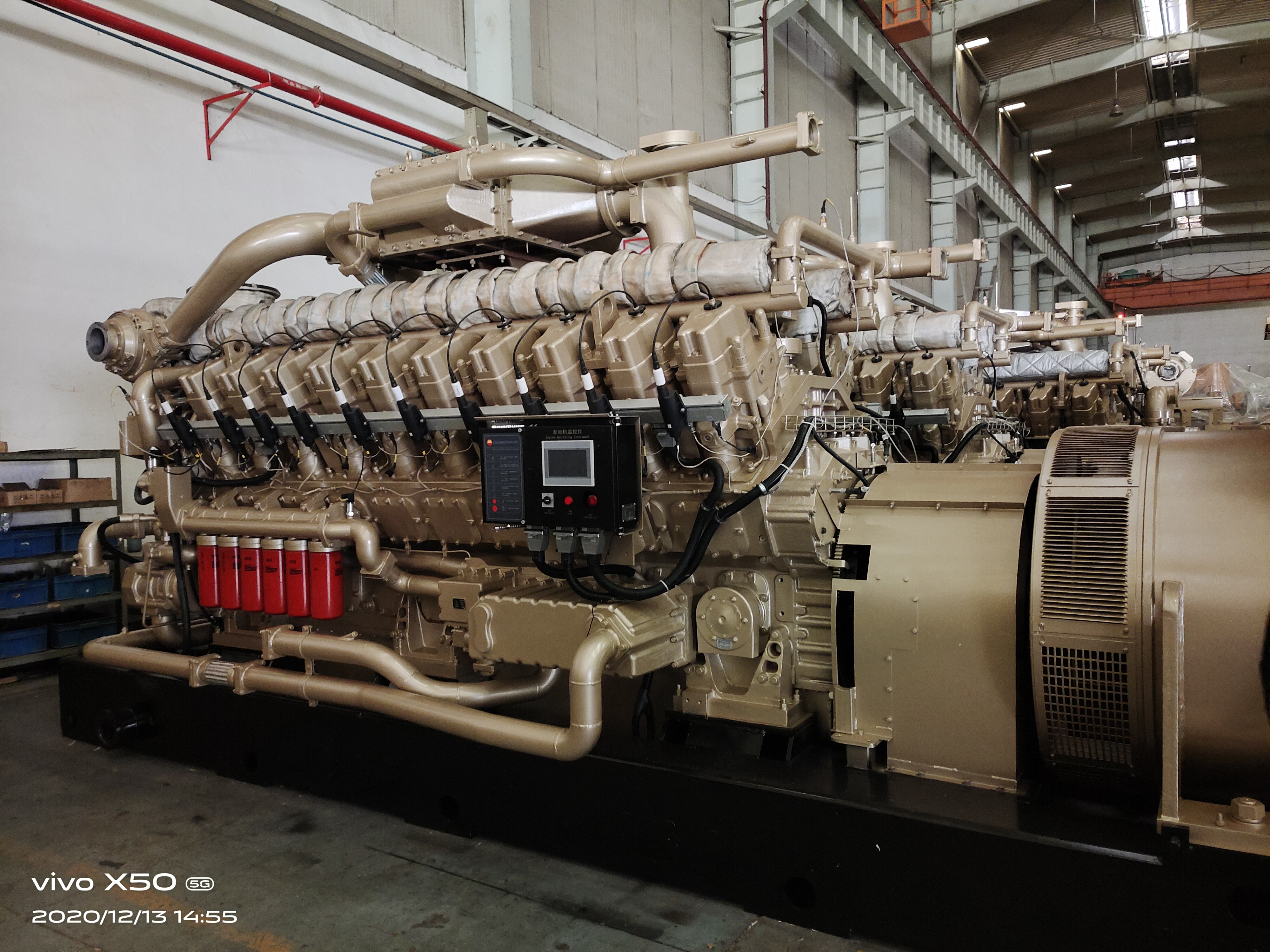

The Fuel Gas Generator Sets

Natural gas generator set is an ignition type gas engine fueled by high calorific value gases such as natural gas, LPG, WTG and associated gas of oil field. On the basis of the non-pressurized model, the supercharging system and the cooling system are added. The cooling system adopts the way of separating high and low temperature circulation, high temperature circulation cooling cylinder, body, cylinder head and other high temperature parts, and low temperature circulation cooling the pressurized gas, air and oil cooler.

Natural Gas Introduction:

The main component of natural gas is methane, with a content of 90%. The nitrogen oxides, hydrocarbons and carbon monoxide produced by combustion are far below the national emission standards, and there is no dust pollution; The heat conversion efficiency of natural gas is 65%, which is equivalent to liquefied petroleum gas and higher than coal. In terms of calorific value, natural gas is already cheaper than coal and far cheaper than oil. Natural gas can be used as civil, power generation, chemical raw material and industrial fuel, etc., to effectively replace coal and oil. For example, it can replace residential coal to gas, replace coal and oil as nitrogen fertilizer raw materials, replace naphtha as ethylene raw materials, replace oil as automobile engine fuel, etc.

LPG is liquefied petroleum gas, the main component of LPG is propane.

CNG is compressed natural gas. The high-pressure natural gas formed by the compression of natural gas to 20MPa is called compressed natural gas (CNG).

WTG is liquefied natural gas, which is called liquefied natural gas (WTG) formed by ultra-low temperature and deep cooling to -162℃.

Unit requirements for natural gas (within 1m from gas inlet valve of gas unit)

CH4 volume content in natural gas ≥70%;

Natural gas pressure 80-200kpa, pressure change rate ≤1kpa/min;

H2S 20 mg/Nm3 or less;

Water content in natural gas ≤40g/Nm3;

Impurity particle size ≤5μm, impurity content ≤30mg/Nm3.

If the combustible gas contains high sulfur and ammonia composition, not only will seriously corrode the spark plug electrode, but also will increase the acid value in the oil, corrosion of the unit internal parts. At the same time easy to generate sediment, increase the wear and corrosion of the engine.

Applicable occasions:

1.Oil field associated gas generation

2. Industrial park

Petroleum processing chemical plant:

1. Use natural gas as a backup power source

2. Oil well supporting single machine to provide power